Taian Kenuo Engineering Machinery Co., Ltd.

- Asphalt Mixing Plant

- LBJ500 Asphalt Mixing Plant

- LBJ800 Asphalt Mixing Plant

- LBJ1000 Asphalt Mixing Plant

- LBJ1500 Asphalt Mixing Plant

- LBJ2000 Asphalt Mixing Plant

- LBJ3000 Asphalt Mixing Plant

- LBJ4000 Asphalt Mixing Plant

- Concrete Batching Plant

- HZS25 Concrete Batching Plant

- HZS35 Concrete Batching Plant

- HZS50 Concrete Batching Plant

- HZS60 Concrete Batching Plant

- HZS75 Concrete Batching Plant

- HZS90 Concrete Batching Plant

- HZS120 Concrete Batching Plant

- HZS150 Concrete Batching Plant

- HZS180 Concrete Batching Plant

- HZS240 Concrete Batching Plant

- Mobile Asphalt Mixing Plant

- SLB Mobile Asphalt Mixing Plant

- QLB Mobile Asphalt Mixing Plant

- Stabilized Mixing Plant

- MWB400 Stabilized Mixing Plant

- MWB500 Stabilized Mixing Plant

- MWB600 Stabilized Mixing Plant

- Diesel Generator Sets

- Cummins Diesel Generator Sets

- Weichai Diesel Generator Sets

- MAN Diesel Generator Sets

- Lovol Diesel Generator Sets

- Volvo Diesel Generator Sets

- Deutz Diesel Generator Sets

- Open Type Generator Sets

- Soundproof Generator Sets

- Mobile Generator Sets

- Automatic Generator Sets

Taian Kenuo Engineering Machinery Co., Ltd.

Add: No. 1, Taidong Industrial Park, Qiujiadian Town, Taishan District, Tai'an City, Shandong Province

Tel: +86-13102801194

Whatsapp: +86-13171887060

Contact Person: Mr. Leo(Director Manager)

E-mail: zgknjx@163.com

Website: www.zgkenuo.com

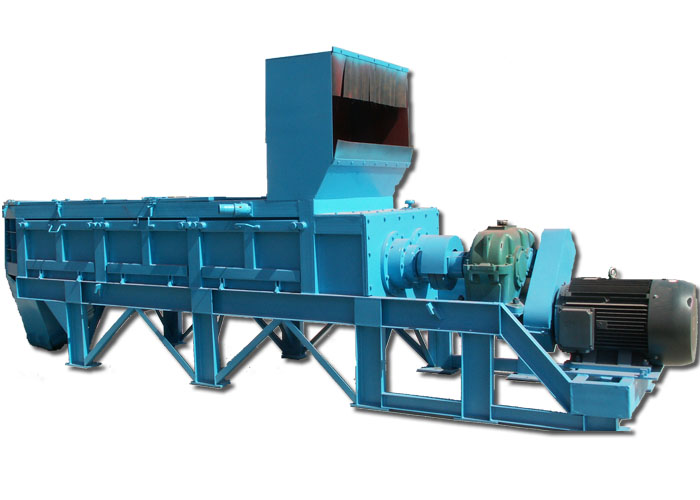

The stabilized soil mixing plant is a kind of mixing plant that produces the highway sub-base material continuously. It adopts two-horizontal shafts forced continuous type mixer with even mixing, productivity of 300-600th and long service life. The computer lelctronic frequency control batching system results in the high automation and high batching accuracy. The volumetric electromagnetic adjusting speed batching system makes it easy to operate and mixing plant.

Convenient to maintain. These series products have three main kinds Modular container. Type mobile type and fixed with total more than 40 kinds, easy moving and installation, The machine cam mix four, five, or six etc many kinds of different size, different kinds of material together and can batch many kinds of mix proportioning concrete.

Ⅰ. Modular container type weighing system

We can adjust the number of batching bins according to the customer requirment. It is easy to install and dismantle and easy to change worksite. The aggregate belt is regulated in advance which save installation time for user.

Ⅱ. Mixing system

Advanced no-scale board force twin-horizontal continuous mixer, there is no need to change scaleboard. The discharging portat mixer bottom makes cleaning convenient and fast. The special wear resisting alloy blade prolongs blade service life. The prolonged mixing shaft and well-distributing mixing blade make mixing sufficient and even solve material isolation.

Ⅲ. Cement supply measuring system

There is different kind collacation of cement silo, the user can choose 50 ton, and 80 ton or 100 ton cement silo according to need.The user can also carry different combination of single silo, double silo and many silos. Basis on it, the user can choose alone measuring or separate measuring. In addition, it is equipped with bag cement conveying system, bucket elevator and so on for user choice. In general, we can carry out special design according to user demand.

The enlarging cement discharging port provent cement arching and make measuring accurate, on basis of this, adding one set pneumatic arch-broken device, enve the cement is not used for a long time, and damping, it can also guarantee the contentious and accurate measuring.

The cement measuring device use overflow reamer and measuring reamer, the big charging port of overflowing reamer make cement full and make sure the continuty and stability of conveying, The discharging port use special overflowing structure, with contentious and stable discharging guarantedd accurate measuring. The measuring reamer user suspension structure, and immune to outside influence. The sensors, PLC, computer and transducer form one set effective measuring control system. After debug parameters, it can realize automatic accurate measuring.